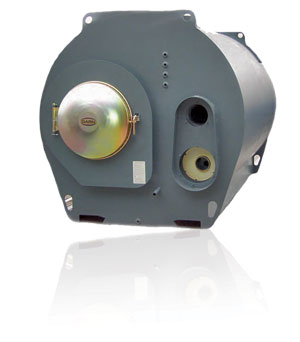

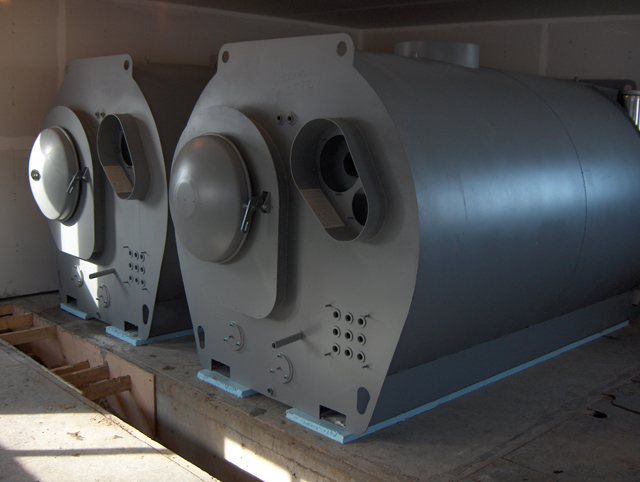

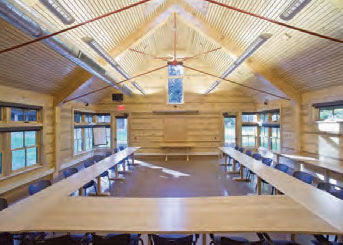

The GARN® WHS is a simple, efficient, and durable wood heating unit. What we manufacture is a state-of-the-art wood fired hydronic heating system with 30 years of tested technology and experience. Our wood burning boilers use a large hydronic thermal storage tank to store the heat from a fast, clean, and efficient wood burning gasification process. GARN® wood heating systems can burn cord wood, slab wood, pallets and other scrap wood, dense wood briquettes, and air-dried corn on the cob. GARN® hydronic heaters produce virtually no smoke because of their patented, two-stage wood gasification technology. A GARN® is not an outside wood furnace, outside wood boiler or an outside wood stove. The GARN® is installed indoors and provides hot water for heating your home, shop, business, or district heating system. All of our models combine high-efficiency wood combustion and hydronic thermal storage to produce the most efficient and simple wood heating units on the market.

Ask anyone who owns a GARN®. Our simplicity, longevity, and efficiency sets us a world apart from anyone else in the wood burning industry. Click here to see a unit in operation.

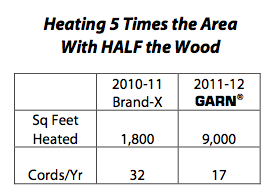

Fuel oil and propane prices are higher than they’ve ever been. Consider a GARN® wood heating system and save money on next year’s bills.

[learn_more caption=”Two-Stage”] low emissions so there is virtually no smoke, creosote, or ash. *Approximately 10 minutes after starting a fire, your GARN® unit burns so efficiently, that it’s virtually smokeless![/learn_more]

[learn_more caption=”Simple”] three moving parts: handle, door, and blower.[/learn_more]

[learn_more caption=”Five-Pass Heat Exchanger”] efficient combustion heat transfer into thermal storage. [/learn_more]

[learn_more caption=”Integrated Thermal Storage”] the GARN® puts the energy of the fire into a large hot water tank. It burns clean, quick, and efficiently. [/learn_more]

[learn_more caption=”Water Delivery”] water has a large specific heat, conductivity, and requires little power to move around. Water delivery ensures efficient transfer of the stored heat to the building or application. [/learn_more]

[learn_more caption=”Easy Integration”] radiant floor, hot water baseboard, cast iron and European style radiators, forced air furnaces, or other heating systems allows the units to be added into existing applications or new construction with ease. [/learn_more]

GARN® units comply with all applicable UL and CSA safety standards, and because of their low exhaust temperatures, are the only wood-fired hydronic heaters certified for both horizontal or vertical flue venting in the United States.

Every GARN® unit ever sold has been 100% manufactured in the USA.

[/tab] [tab]

[/tab] [tab] [/tab] [/tabs]

[/tab] [/tabs]