Slider 5

We asked Ernie (mid-eighties young) if we could return in another 16 years for another update. He agreed. Not much else can be said…….he is a man of his word and we will be back.

First unit tested with cordwood to be approved by the EPA!

Meets all NSPS emissions limits for 2020 and beyond!

Only hydronic cordwood unit listed to the Canadian standard CSA B415.1-2010!

Every WHS-1500 and WHS-2000 installed since 1989 is approved!

It’s December 2014 and the price of oil (and gasoline) has dropped about 40% from $107/barrel to about $61/barrel, within the last 6 months. Why? There are a number of reasons floating about, including:

I’m not sure which is correct, if any? Are you? In my view it would be prudent to conserve the oil for critical uses (such as plastic manufacturing and medical uses) rather than “wasting it” through inefficient transportation or space heating. Instead there has been a spike in the purchase of trucks and large SUV’s. And the US still does not have a clearly defined comprehensive energy policy. This is beginning to sound an awful lot like the 70s’ and 80’s. What in the hell has Congress been doing for the last 44 years?

If we have learned anything from the past, this drop in prices will not last. In a year or two the price of oil will spike higher than it was prior to its dive and stay there for the future. Oil reserves are not infinite; they do have a finite life. As my friend and mentor Raymond Plank (Founder of Apache Oil) recently pointed out: it takes a million years to form a barrel of oil, but only 80 years to grow a tree. Oil pricing will ebb and flow, low and high forever. Its pricing is very volatile, connected as much with politics as it is with supply and demand. In my view, oil extracted from tar sands should be considered criminal abuse of our planet.

So the next time you look at a tree consider what it does for you: provides beauty for the eye, scrubs CO2 from the atmosphere, provides shelter for animals, provides lumber for housing and provides fuel for warmth. Such a versatile, beautiful living creation.

The GARN® team hosted another very successful Open House at its warehouse and test facility in Arden Hills, MN on Saturday August 23, 2014. Attendees got to meet the GARN® team, experience a cordwood test burn of a GARN® 1000, as well as enjoyed lunch and refreshments. As a team, we certainly enjoy meeting our customers, answering their questions and demonstrating the clean, efficient burn for which GARN® equipment is noted.

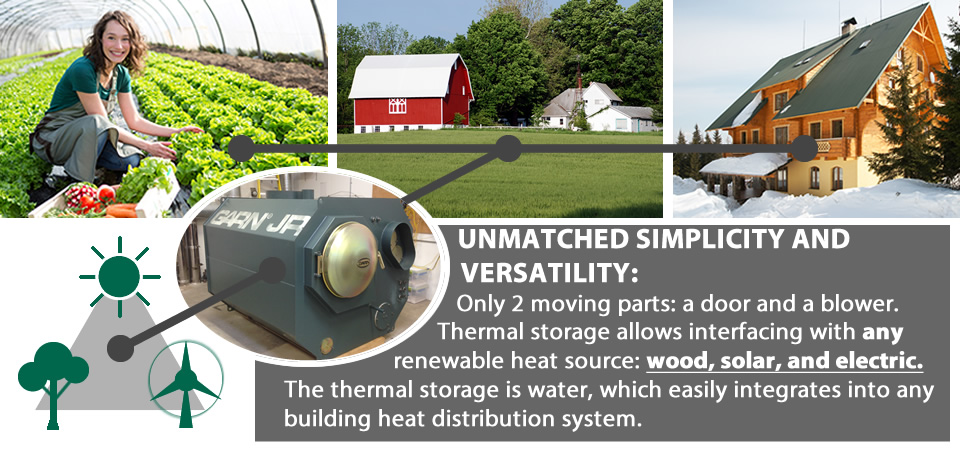

Find out more about GARN®’s latest product, the GARN® JR. All the features and quality of a GARN® unit in a package that’s easy on the wallet.

[tabs slidertype=”simple” fx=”slide”] [tab]

Green Mountian Technology & Career Center

Hardwick, VT

Black River Design

7,000 Square Feet

Single GARN® 3200 (950,000 BTUH) with biodiesel backup providing district heat for:

Site: Ucross Foundation in Clearmont, WY

Year Built: 1882

Size: 13,000 sq. ft.

Existing heating system: 2 propane boilers

New System:

Wood Source:

Construction start/end: November, 2007 – July, 2008 Annual fuel savings: 2,500 gallons of propaneProject manager and overall concept: Martin Lunde, PE, Dectra CorporationHVAC design: McKinley Wood, PEConstruction Supervision: Ken Thorpe, Powder River The Ucross project was funded by the Ucross Foundation, through generous support from Ucross Founder Raymond Plank, with the on-site personnel support of: Director Sharon Dynak, maintenance guru Mike Latham and other Ucross staff.

[tabs slidertype=”simple” fx=”slide”] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [tab]

[/tab] [/tabs]

For information about the Ucross Fundation visit:

http://www.ucrossfoundation.org/

For information about GARN® products and projects in the New England area, please contact our local representative:

Project coordinators and people interested in alternative energy meet at Taos Pueblo New Mexico, March 7 2008, to fire up the biomass district heating system at The Red Willow Education Center. NOTE: Carl Rosenberg is misidentified as Ryan Rose in the piece. Video by Rick Romancito, editing by Melody Romancito, for The Taos News Media Center

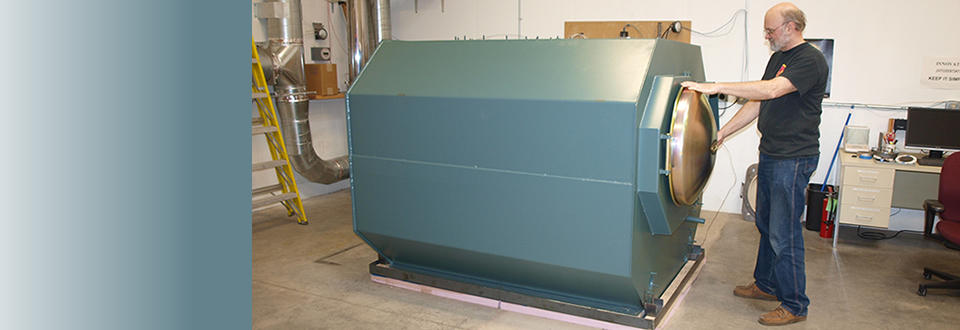

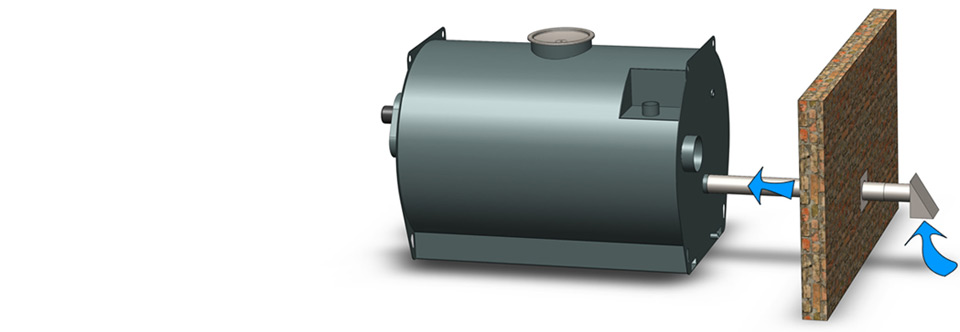

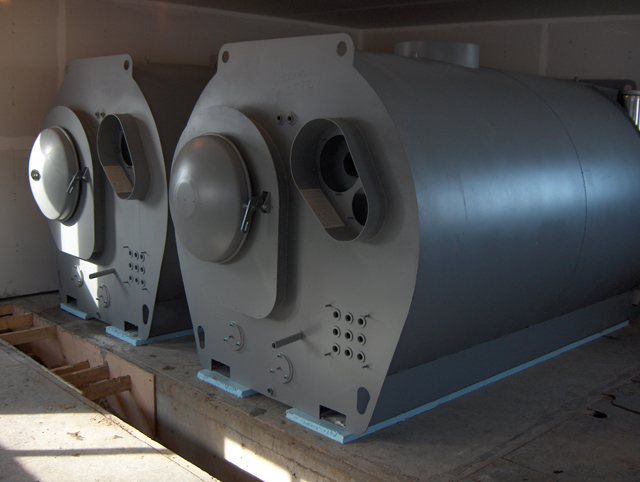

A GARN® WHS 1500 unit at the factory ready for shipment.

A GARN® WHS 1500 unit installed inside of a building.

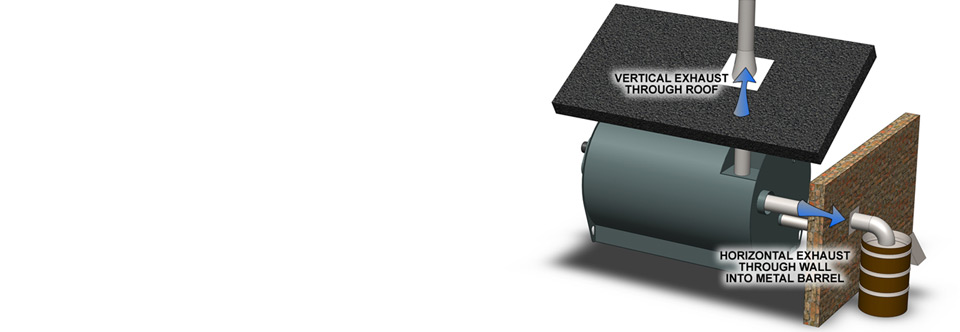

The GARN® WHS unit operating. Notice NO SMOKE backdrafts.

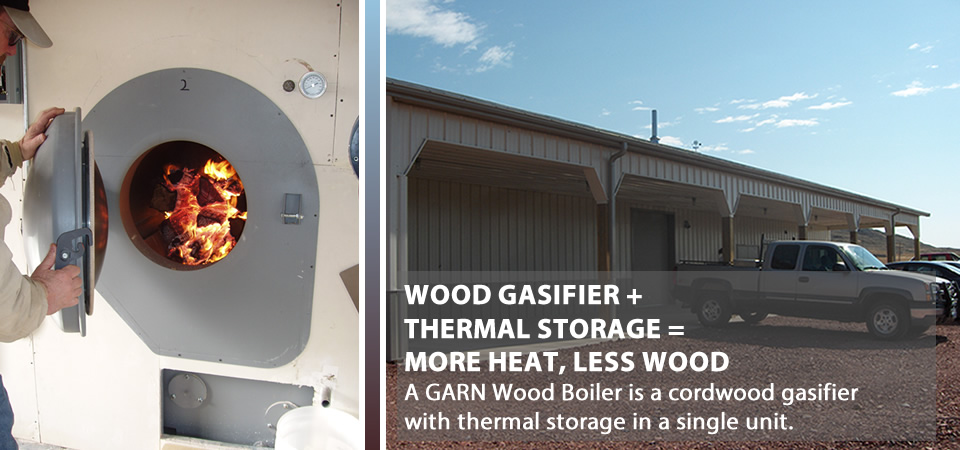

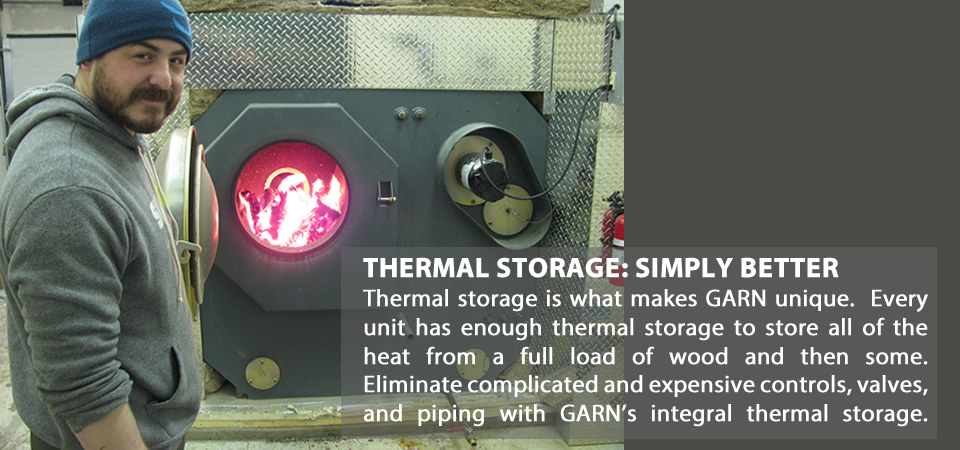

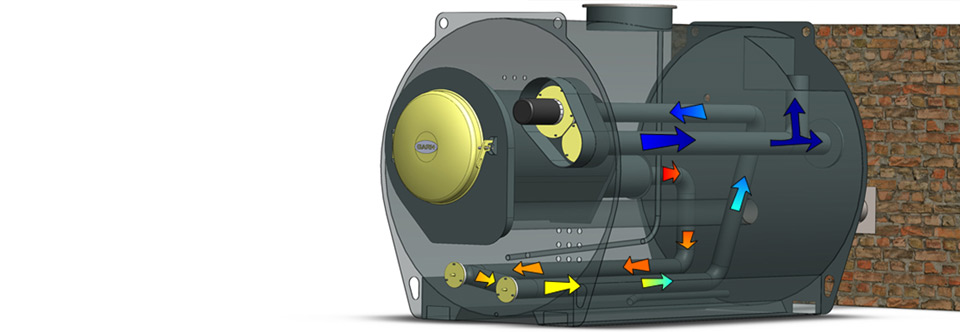

The GARN® WHS is a simple, efficient, and durable wood heating unit. What we manufacture is a state-of-the-art wood fired hydronic heating system with 30 years of tested technology and experience. Our wood burning boilers use a large hydronic thermal storage tank to store the heat from a fast, clean, and efficient wood burning gasification process. GARN® wood heating systems can burn cord wood, slab wood, pallets and other scrap wood, dense wood briquettes, and air-dried corn on the cob. GARN® hydronic heaters produce virtually no smoke because of their patented, two-stage wood gasification technology. A GARN® is not an outside wood furnace, outside wood boiler or an outside wood stove. The GARN® is installed indoors and provides hot water for heating your home, shop, business, or district heating system. All of our models combine high-efficiency wood combustion and hydronic thermal storage to produce the most efficient and simple wood heating units on the market.

Ask anyone who owns a GARN®. Our simplicity, longevity, and efficiency sets us a world apart from anyone else in the wood burning industry. Click here to see a unit in operation.

Fuel oil and propane prices are higher than they’ve ever been. Consider a GARN® wood heating system and save money on next year’s bills.

[learn_more caption=”Two-Stage”] low emissions so there is virtually no smoke, creosote, or ash. *Approximately 10 minutes after starting a fire, your GARN® unit burns so efficiently, that it’s virtually smokeless![/learn_more]

[learn_more caption=”Simple”] three moving parts: handle, door, and blower.[/learn_more]

[learn_more caption=”Five-Pass Heat Exchanger”] efficient combustion heat transfer into thermal storage. [/learn_more]

[learn_more caption=”Integrated Thermal Storage”] the GARN® puts the energy of the fire into a large hot water tank. It burns clean, quick, and efficiently. [/learn_more]

[learn_more caption=”Water Delivery”] water has a large specific heat, conductivity, and requires little power to move around. Water delivery ensures efficient transfer of the stored heat to the building or application. [/learn_more]

[learn_more caption=”Easy Integration”] radiant floor, hot water baseboard, cast iron and European style radiators, forced air furnaces, or other heating systems allows the units to be added into existing applications or new construction with ease. [/learn_more]

GARN® units comply with all applicable UL and CSA safety standards, and because of their low exhaust temperatures, are the only wood-fired hydronic heaters certified for both horizontal or vertical flue venting in the United States.

Every GARN® unit ever sold has been 100% manufactured in the USA.