Habitat for Humanity of Dane County, WI presented Hank Daum and Heidi River, owners of an innovative barn conversion, with the first ReStore Project of the Year Award in September 2012. Daum and River spent six years remodeling a barn into an energy-efficient home with many materials purchased from the Habitat ReStore.

The three inches of closed-cell polyurethane foam used to encapsulate the Barome project yields a maximum R-value of about 21, which is not outstanding given the total area of 9,000 sq ft. Most of their energy savings is due to the GARN® method of wood heating–hot, fast, and smokeless using thermal storage and no smoldering “idle” combustion condition–which we at GARN® maintain is the only way to burn wood efficiently and cleanly.

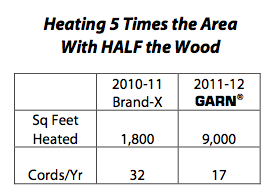

Daum and River sing the praises of their GARN® wood heating system. During the 2010-2011 heating season, they used a Brand X outdoor wood burner to heat their old 1,800 sq. ft. farmhouse, using 32 cords of wood and needing to load it twice a day every day from November through April to maintain a temperature of only 64 degrees on the coldest days.

In their new, 9,000 sq. ft. home (five times the square footage of the old farmhouse) in the 2011-2012 heating season using the GARN® wood heater, they used just 17 cords of wood and were able to keep the temperature steadily between 72-74 F with a maximum of two 3-hour burns per day, with single burns needed in November and April.

Their old leaky farmhouse was used by the local fire department for training.

To download a PDF of this article, Click Here.